FC Neostar / FI Neostar: Hochleistungs-Rückkühler mit effizienter Ventilatortechnologie

Effiziente Rückkühler

Umfassender Klimaservice seit 1949

Steigender Kühlbedarf in der Industrie: Maßgeschneiderte Lösungen für maximale Effizienz und Langlebigkeit

In der industriellen Fertigung wächst der Bedarf an Kühlung seit Jahrzehnten kontinuierlich. Hinzu kommt, dass die Anforderungen in der Industrie und im produzierenden Gewerbe immer vielfältiger und komplexer werden. Egal ob Prozess-, Prüfstands- oder Maschinenkühlung, Lebensmittelproduktion oder Tiefkühllager – für eine anwendungsgerechte Beratung und Ausrüstung sind Fachwissen und Erfahrung unabdingbar. Als Klimaspezialist bieten wir kundenspezifische Lösungen für maximale Effizienz, kombiniert mit einer hohen Verfügbarkeit und langen Lebensdauer bei minimalen Betriebskosten

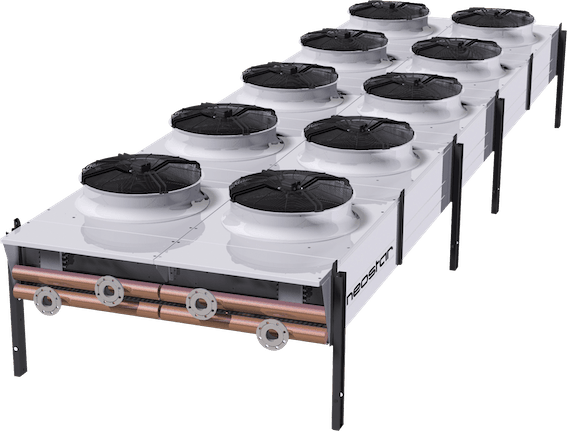

FC NEOSTAR „City“

Kompaktheit und hohe Leistung.

FI NEOSTAR „Industry“

Geringer Druckverlust und hohe Leistung, Baureihe bis auf 1200 kW erweitert, Druckverlust optimiert.

Hauptanwendungen

Klimatisierung, „free cooling“, Kraft-Wärme-Kopplung, Stromaggregate, Prozess- und Industriekälte sowie Abkühlung aller kupferkompatiblen Medien, deren maximale Temperatur am Eintritt nicht über 100°C liegt.

Untitled

Beschreibung

Sinnvoller Ersatz für Kühltürme.

Gehäuse

Das Gehäuse ist aus verzinktem Stahlblech sowie aus verzinktem, in weißer Farbe vorlackiertem Stahlblech gefertigt. Die Verwendung von rostfreien Edelstahlschrauben garantiert eine ausgezeichnete Korrosionsbeständigkeit (Norm ISO 7253) und ein dauerhaft ästhetisches Aussehen. Alle Komponenten wurden erfolgreich den Korrosionstests (Salzsprühnebel und Kesternich-Test) unterzogen. Die Geräte werden für den Transport auf einem Holzsockel verschraubt.

Ventilator

Die FC/FI NEOSTAR-Baureihe ist mit Ventilatoren 400V/3/50Hz (Klasse F) mit Außenläufermotoren, zwei Drehzahlbereichen (Stern-Dreieck-Schaltung) ausgerüstet.

Die FCH/FIH NEOSTAR-Baureihe ist mit Ventilatoren 400V/3/50Hz (Klasse H) mit Außenläufermotoren, zwei Drehzahlbereichen (Stern-Dreieck-Schaltung) ausgerüstet.

Es handelt sich um geschlossene Motoren mit Langzeitschmierung 400V/3/50Hz, IP54, entsprechend der Norm EN 60529. Die Lüftermotoren sind standardmäßig verdrahtet und werkseitig wie folgt angeschlossen:

- 1 – 3 Klemmenkästen für die L-Modelle (in Reihe geschaltet),

- 2 – 8 Klemmenkästen für die P-Modelle (parallel geschaltet).

Die Geräte können auf Wunsch unverdrahtet geliefert werden (Option SCU).

Die Schutzgitter entsprechen den geltenden Normen.

Zum Betrieb Ihrer Anlage unter optimalsten Bedingungen sind als Option Ventilatoren mit elektronisch kommutierten Motoren (Option MEC) erhältlich.

Ventilatoren mit besonderen Spannungen (FC/FI NEOSTAR):

- M60: Motoren Ø 910 mm, 400 V/3/60Hz, IP54, Klasse F, 6-polige Version

- M26: Motoren Ø 910 mm, 230 V/3/60Hz, IP54, Klasse F, 6-polige Version

- M25: Motoren Ø 800 mm, 230 V/3/50Hz, IP54, Klasse F, 6- und 12-polige Version.

Wärmetauscher

Die Rückkühler sind mit Wärmetauschern mit folgenden Kenndaten ausgerüstet:

- Kupferleitungen in versetzter Anordnung mit wellenförmigen Aluminiumlamellen für einen optimalen Wärmeaustausch.

- Sammelrohre mit Entlüftungs- und Ablaufstutzen.

- Standardanschlüsse Stahlrohr mit Flansch.

Als Option:

- Vinylbeschichtung (BAE) oder Blygol Polual XT Beschichtung (BXT) auf dem Wärmetauscher für eine verbesserte Korrosionsbeständigkeit in aggressiven Atmosphären.

- Überlagerte Kreisläufe HT / NT

Vorteile

- Einfache und kostengünstige Installation (Stahlrohre)

- Niedrige Wartungskosten dank der direkt angetriebenen Ventilatoren

- Keine Verunreinigung durch Luft- und Wasserbakterien

- Kein Wasserverbrauch

- Keine Dampfemission

- Einfache Regelung der Flüssigkeitstemperatur im Winter

- Optimierte Lösung (Schallpegel, Energieverbrauch, Größe, Art der Temperaturregelung…) aufgrund der Vielzahl an Wahlmöglichkeiten

- Nachhaltige Leistung dank der verschiedenen Klappenarten

Wichtiger Hinweis

Die Leistung eines Rückkühlers hängt stark von den Betriebsbedingungen ab. Mit unserer Auswahlsoftware ist es möglich, den für Ihren Bedarf am besten geeigneten Rückkühler auszuwählen. Bitte nehmen Sie Kontakt mit uns auf.

Anfrage zur Berechnung des Rückkühlers

Haben Sie Fragen zu FC / FI Neostar?

Die FC Neostar / FI Neostar Rückkühler sind mit robusten Ventilatoren ausgestattet, die in zwei Drehzahlbereichen arbeiten. Mit optionalen, elektronisch kommutierten Motoren bieten sie eine effiziente und zuverlässige Industriekühlung. Kontaktieren Sie uns, um mehr über diese leistungsstarken Rückkühler und ihre Anpassungsmöglichkeiten zu erfahren!